Decorative Laminates: The Unsung Heroes of Modern Interior Design

October 27, 2025

How to Style Your Workspace Using FENIX Super Matt Materials

November 19, 2025Pick the wrong surface material, and a space feels off. That sleek kitchen or polished office look? It’s less about the furniture and more about what covers the counters, cabinets, and walls. HPL sheets keep showing up in projects because they actually solve problems designers face.

It’s not about trends. HPL works because it looks decent and holds up in real use. Clients don’t want beautiful countertops that chip after six months or cabinet fronts that show every fingerprint. They want both, something attractive that doesn’t fall apart.

Why are more people using HPL sheets now? Three things: they perform under pressure, they come in enough styles to work with different aesthetics, and they’re not a nightmare to install. That matters whether you’re the designer planning the space or the person who’ll be cleaning coffee spills off the counter every morning.

This post explains why HPL has become common in modern projects and why it’s stuck around while other materials have come and gone.

What exactly are HPL Sheets?

HPL means High-Pressure Laminate. Basically, they take paper layers, soak them in resin, then crush everything together under extreme heat and pressure. Sounds simple, but what you get is pretty tough stuff that can mimic almost any surface, wood grain, smooth glass, stone textures, whatever.

Why does HPL pop up in so many places? Three reasons: it won’t wreck your budget, it actually holds up, and you’re not stuck with limited choices. Walk into an office, someone’s home, or even a factory floor, chances are you’ll spot HPL somewhere. The design range is legitimately wide, which is why builders and designers keep using it. It just works for most projects without overthinking it.

Why Designers love HPL Sheets

Finding materials that are both practical and aesthetically pleasing can be difficult for designers. HPL sheets fulfil every requirement. Let’s examine the main reasons HPL sheets are now the go to option for designers.

1. A Wide Range of Designs and Finishes

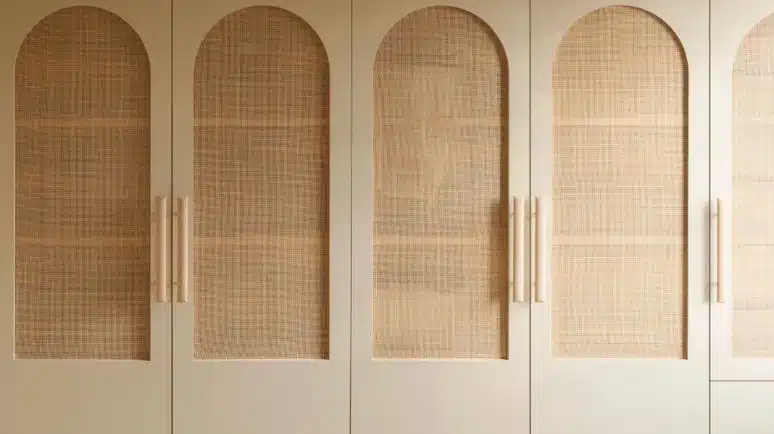

What stands out about the HPL sheet is how many different looks it can pull off. Want a matte finish? Done. High-gloss shine? No problem. Something that feels like real wood when you touch it? They make that too. This flexibility means designers can create a consistent look throughout a space without hunting down five different materials or blowing the budget.

You’ll find HPL that mimics traditional wood panelling, versions that look like expensive marble, and everything in between. It’s practical: one material that handles multiple design needs while staying durable. Whether you’re working on a home or a commercial space, you can get a modern, polished result without the usual compromises between appearance and function.

2. Durability that Designers can Count on

Looking good matters, but not if it can’t handle real life. Walk through any busy office, retail store, or commercial kitchen, and these places take a beating. HPL sheets work in these spots because they can handle what gets thrown at them. Scratches from moving furniture, coffee spills, and the occasional dropped tool don’t do much damage.

Wood’s a different story. Please leave it in a humid kitchen, and it will warp. Please put it in a sunny spot, and the colour fades. HPL doesn’t have these problems. It looks the same after five years as it did on day one.

Designers like this because their clients aren’t calling them back to complain about surfaces that fell apart. You build something that looks sharp, and it stays that way. Simple as that.

3. Affordable yet Premium

Let’s talk about what HPL actually costs. Marble or granite? You’re looking at serious money, often enough to blow through a project budget before you’ve even started. HPL sheets give you a comparable look for way less. That’s not a slight difference. It’s the kind of gap that lets designers say yes to projects they’d otherwise have to scale back.

Here’s the reality: most clients want spaces that look expensive. Few actually want to spend costly money. HPL bridges that gap. Need countertops that look like Carrara marble? Cabinet doors with a wood grain that reads as custom millwork? Wall panels that feel premium? HPL handles it all without sticker shock.

The quality isn’t fake or cheap either. You’re getting material that performs well and looks right. For designers juggling client expectations and actual budgets, that combination matters more than just about anything else.

4. Easy Maintenance

Keeping surfaces looking clean gets old fast, especially anywhere food or liquids are involved. HPL sheets make this easier. Spill coffee on one? Wipe it off. No staining, no drama. You’re not scrubbing or using special cleaners; just basic cleaning does the job.

This matters most in commercial spaces where appearance counts but nobody has time for high-maintenance materials. Cafés need tables that can handle constant use and still look decent. Healthcare facilities can’t have surfaces that harbour stains or require complicated cleaning protocols. HPL handles both situations without much fuss. It’s practical in a way that saves time and headaches, which is precisely what busy environments need.

5. Sustainability and Eco-Friendliness

Every designer talks about sustainability now. HPL actually holds up better in that conversation than most people realize. Plenty of manufacturers make these sheets from recycled materials, so you’re not using fresh resources for every project.

This hits differently when you’re the one specifying materials and wondering what happens five years down the road. HPL isn’t some miracle solution; nothing is compared to alternatives that fall apart or need constant replacement. It’s clearly better.

Here’s what really matters: lifespan. Something that lasts a decade or more means less garbage. You’re not ripping it out and sending it to a landfill every few years. Manufacturers aren’t producing endless replacements. And depending on where you are and which product you choose, some HPL gets recycled again when it’s finally done.

Looking to make choices that don’t destroy the planet as much? HPL makes sense. It won’t solve climate change, but it’s progress in the right direction.

6. Customizability for Every Project

HPL sheets work across a range of projects, including whole renovations, office buildouts, and ground-up construction. The selection of colours, textures, and patterns is broad enough that you can find something that fits what you’re going for. Need it to look like reclaimed wood? There’s a finish for that. Want a stone texture without the weight and cost? HPL handles it. The same goes for metal looks.

Also read: Why HPL Sheets are the Hidden Hero of Modern Interiors

What’s practical about HPL is the flexibility in sizing and customization. Need large panels for a feature wall? Done. Working with unusual dimensions or detailed patterns? That’s manageable, too. This adaptability means HPL fits into contemporary minimalist spaces just as easily as it does into more traditional designs. You’re not forcing your project into a narrow set of options; the material bends to what you’re actually trying to build.

Applications of HPL Sheets in Design

HPL sheets work in many different situations. Countertops, wall cladding, and cabinet doors, the material adapts to whatever you need. Here’s where designers typically use them:

- Kitchens: Counters and backsplashes get destroyed. Hot pans land directly on them, red wine spills, knives slip. HPL takes this punishment without staining or burning. Want the marble look without having to seal it every year? Or walnut grain without worrying about water damage? HPL gives you that. The design options are broad enough to match whatever style you’re after, and the surface actually survives what happens in a real kitchen.

- Furniture and Cabinets: HPL can be used for a lot of furniture, including desks, storage units, and built-ins. The material gives you clean lines and a contemporary feel. With different textures and finishes available, you can create something that looks intentional rather than picking whatever’s in stock. And it’s not just about looks; the surfaces hold up to use.

- Wall Panels: Walk into most commercial buildings and you’ll see HPL on the walls. Hotels, offices, and retail stores use it because it looks finished and won’t need to be replaced for 2 years. The variety of HPL sheet designs means you’re not stuck with a single generic option. You can actually match the space you’re trying to create.

- Office Spaces: Designers continue to choose HPL for workspaces because it appears contemporary and polished without being ostentatious. When attempting to create a certain mood, it’s helpful to be able to modify finishes rather than settle for conventional selections. Practically speaking, office furniture is subjected to a lot of wear and tear; HPL is better equipped to withstand this than materials that look fantastic in the showroom but break under regular use.

Conclusion

Designers keep coming back to HPL sheets for a straight forward reason: they check multiple boxes at once. You get durability, visual flexibility, and reasonable pricing, all in one material. That combination is complex to beat when you’re working on either commercial projects or residential spaces.

What makes HPL practical is the range. Want a high-end look without the high-end budget? HPL delivers. Need something customizable that won’t fall apart in a few years? Same answer. The material handles wear and tear while offering enough design variety to fit different aesthetics.

Here’s the thing: sustainability matters now more than ever, and HPL performs well there, too. It lasts longer than cheaper alternatives, leading to fewer replacements and less waste.

So if you’re mapping out a project and trying to balance looks, longevity, and cost, HPL sheets deserve serious consideration. They’re not flashy or complicated. They work across many different scenarios, which is precisely what most projects need.

FAQs

Absolutely! HPL sheets are known for their exceptional strength and resistance to scratches, stains, and moisture. Whether used in kitchens, offices, or commercial interiors, they can easily handle daily wear and tear without losing their charm. Designers often choose HPL sheets because they stay looking new for years with minimal maintenance.

Almost anywhere! They’re suitable for kitchen countertops, cabinets, wall panels, furniture, office interiors, hospital surfaces, and even exterior cladding, depending on the type. Their versatility makes them a designer favourite.

One of the most significant advantages of HPL sheet design is variety. You can choose from countless textures, patterns, and colours, from elegant wood grains to contemporary solid shades and metallic finishes. This versatility allows designers to match the material to any style, whether it’s minimalist, industrial, or luxurious.